Cement Manufacturing Process | Phases | Flow …

30.08.2012 · Cement Manufacturing Process Phase IV: Kiln Phase. Kiln is a huge rotating furnace also called as the heart of cement making process. Here, raw material is heated up to 1450 ⁰C. This temperature begins a stone reaction so called decarbonation. In this reaction material (like limestone) releases the carbon dioxide. High temperature of kiln ...

Cement Production Process Diagram - …

Cement Production Process Diagram. The fig1 show the flow diagram of the dry process of the manufacture of cement 1 dry process in the dry and semidry process the raw materials are crushed in a dry state then they are processed in grinding mill dried and reduced to very fine powderlike that dry power is further blended corrected for the right composition and mixed

Cement Manufacturing Process Simplified Flow …

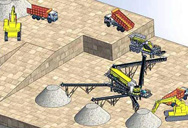

11.05.2013 · Cement manufacturing process - components of a cement plant from quarry to kiln to cement mill.

Cement Manufacturing Process: What is Cement …

Flow Diagram of Cement Manufacturing Process by Wet Method. (ii) Burning or Calcination of the Dry mix: The well proportioned finely powdered mixture is charged into a long steel cylinder, called the Rotary Kiln. The kiln is adjusted in an inclined position, making an angle of 15 degrees with the horizontal and rotates around its longer axis (hence the name suggests). It has a …

IELTS Task 1 Process- Cement & Concrete …

14.04.2015 · The diagrams illustrate the phases and apparatus to make cement and how cement is utilised in the production of concrete for construction. The production of cement involves a 5 stage, linear process that begins with the mixing of raw materials and culminates in the packaging of new cement. Making concrete is a simpler process that involves mixing four …

Diagram Of The Cement Production Line Project

diagram of the cement production line project. Execution of a cement project from AZ FL. capital investments. However, the kiln system only accounts for around 25% of the value of a cement production line and additionally, the lifetime of a kiln is. Project Management Plan of Vista Cement Plant Project. conducted by several sources, indicate that if the production of cement …

Parametric Studies of Cement Production …

The cement industry is one of the most intensive energy consumers in the industrial sectors. The energy consumption represents 40% to 60% of production cost. Additionally, the cement industry contributes around 5% to 8% of all man-made CO 2 emissions. Physiochemical and thermochemical reactions involved in cement kilns are still not well understood because of …

Cement manufacturing - components of a …

For a more detailed account of the cement production process, see the Understanding Cement book. View of a cement kiln (the long nearly-horizontal cylinder) and preheater tower. (Picture courtesy Castle Cement.) Summary of production process. Cement is typically made from limestone and clay or shale. These raw materials are extracted from the quarry crushed to a …

The Cement Manufacturing Process - Advancing …

Domestic cement production has been increasing steadily, from 66.4 million tons in 2010 to about 80.5 million tons of Portland cement in 2014 according to the U.S. Geological Survey 2015 Cement Mineral Commodity Summary. The overall value of sales of cement was about $8.9 billion, most of which was used to make an estimated $48 billion worth of concrete. Most …

process of cement production in flow diagram - …

We have process of cement production in flow diagram,Aug 30, 2012· The remainingcementis shipped in bulk quantities by mean of trucks, rails or ships.CementManufacturingProcess Flow Chart. After explaining the completeprocess of cementmaking,flow chartwould be like that.flow chartpresent the summary of wholeprocessas shown below.

Cement Manufacturing - A Wet Process With …

The process out clinker is cooled and ground to a fine powder with the addition of about 3 to 5% of gypsum. The material produced by this process known as Portland cement. The cement manufacturing is done by majorly by two methods known as wet process and dry process depending on their mixing is done with water or without water.

Cement Grinding Process Diagramm With Ball …

Cement Grinding Process Diagramm With Ball Mill. Optimization of Cement Grinding Operation in Ball Mills Several energy efficient options for cement grinding are available today such as vertical roller mills roller presses typically in combination with a ball mill and clinker pregrinders with. Whatever your requirements, you ll find the perfect service-oriented solution to match …

11.6 Portland Cement Manufacturing

17.08.1971 · The balance of domestic cement production is primarily masonry cement. Both of these materials are produced in portland cement manufacturing plants. A diagram of the process, which encompasses production of both portland and masonry cement, is shown in Figure 11.6-1. As shown in the figure, the process can be divided into the following primary …

cement production block diagram - …

XSM stone crushing machine projectgrinding unit cement plant process in block diagram ShangHai XSM grinding unit cement plant process in block diagram are a professional production of stone crushing machineSales and Widely used in Europe, South America, Africa, East Asia and Asia region. Chat Online . Get Price. Emissions from the Cement Industry. May 09, 2012 · Its production …

Cement Ball Mill Process Diagram- LEMINE …

Diagram Of Cement Mill. Cement kiln diagram crusher ball mill mechanic machine cement manufacturing by wet process the raw materials are calcareous materials like limestone or chalk and argillaceous material such as shale or clay burning this composition in a kiln at a temperature of about 1300 to 1500c cement manufacturing a wet process with the flow diagram in the wet process cement ...

(PDF) Analysis of material flow and consumption …

Cement production, which is highly dependent on the availability of natural resources, will face severe resource constraints in the future. This is especially true for the cement industry in China.

IELTS Process Diagram Examples

These diagrams illustrate the process of making cement first, followed by a visual explanation of concrete’s production. While cement is made through a sequence of much more passages, concrecte’s production seems to be easier as it requires less features.