Crusher Reduction Ratio - Mineral Processing & …

What is the impact of the Crusher Reduction Ratio on crusher performance.

Cone Crushers | McLanahan

31-5-2018 · A Cone Crusher will deliver a 4:1 to 6:1 reduction ratio. As we set the closed side setting tighter to create a finer output, we also reduce the volume or throughput capacity of the machine. Generally speaking, multiplying the closed side setting by two is a good guide to the top size of the gradation exiting the machine.

Reduction Ratio Of Cone Crusher - krosline.nl

Cone Crusher Reduction Ratio. Cone crusher reduction ratioe powerscreen1300 maxtrak is a portable cone crushing plant which is ideally suited to secondary applications such as taking an all in feed from a primary crusher based around the 1300 automaxcone crusher, the plant excels in the production of subbase or aggregates, providing excellent ...

Reduction Ratio For Cone Crusher Pdf - HeNan …

Reduction ratio for cone crusher pdf. high reduction ratio crusher - Alibaba Alibaba.com offers 167 high reduction ratio crusher products. About 46 of these are crusher. A wide variety of high reduction ratio crusher options are available to you such as hammer crusher impact crusher and cone

reduction ratio of jaw crusher - deserviezen.nl

reduction ratio of jaw crusher. Home; reduction ratio of jaw crusher; Get Price Here ... CS Cone Crusher. Comparing with other kinds of crushers, CS Series spring cone crusher …

Cone Crusher - an overview | ScienceDirect Topics

Cone crushers were originally designed and developed by Symons around 1920 and therefore are often described as Symons cone crushers. As the mechanisms of crushing in these crushers are similar to gyratory crushers their designs are similar, but in this case the spindle is supported at the bottom of the gyrating cone instead of being suspended as in larger gyratory crushers.

Crusher Size Reduction Ratio Calculation Method

Generally, every crusher machine is not the same, here are several common crusher size reduction ratio: The impact crusher size reduction ratio is 20 to 1. The vertical shaft impact crusher size reduction ratio is 4-8 to 1. The vertical roller mill size reduction ratio is 2-2.5 to 1. The hammer crusher size reduction ratio is 20 to 1.

Reduction Ratio Of A Crusher - restaurant-le-billot.fr

reduction ratio for cone crusher pdf - De Balans. Crusher Reduction Ratio - 911metallurgist. We know from our examination of the crushing characteristics of these types that, for equal reduction ratios, the volume-reduction-ratio in the standard gyratory is considerably higher than it is in the fine reduction crusher.Reduction Ratio Formula For CrusherCalculation Of Reduction Ratio In Roll ...

What affects cone crusher performance? — …

These are the two main causes of sub-optimal crushing performance, but losses in the reduction ratio can also be caused by selecting the wrong mantle or by having a poor chamber profile or design. Surprisingly, selecting the wrong alloy has no effect when it comes to the reduction ratio (although this will affect the life of wearable parts in your crusher).

TECHNICAL NOTES 5 CRUSHERS - Mineral Tech

Jaw crushers are operated to produce a size reduction ratio between 4:1 and 9:1. Gyratory crushers can produce size reduction ratios over a somewhat larger range of 3:1 to 10:1. The primary operating variable available on a crusher is the set and on jaw and gyratory the open-side set (OSS) is specified. This reflects the fact that considerable ...

(PDF) SIZE REDUCTION BY CRUSHING METHODS

4-3-2017 · crushers and cone crushers whereas rod m ills and ball mills, ... All crushers have a limited reduction ratio m eaning that size reduction will take place in stages.

Cone Crusher Reduction Ratio

Jaw crushers offer reduction ratios of up to about 6:1, while cone crushers can reduce material size up to a maximum of 8:1 ratio. The finer the crushing, the smaller the reduction ratio. As a basic rule, jaw crushers are the primary crusher taking the mined aggregate and reducing it to a size that a cone crusher can accept.

do reduction ratio of jaw crusher is ratio of d is to d

Jaw crushers offer reduction ratios of up to about 6:1, while cone crushers can reduce material size up to a maximum of 8:1 ratio. The finer the crushing, the smaller the reduction ratio. As a basic rule, jaw crushers are the primary crusher taking the mined aggregate and reducing it to a size that a cone crusher can accept. get price

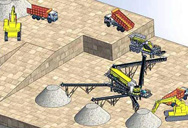

Crusher - Wikipedia

A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, sand or rock dust.. Crushers may be used to reduce the size, or change the form, of waste materials so they can be more easily disposed of or recycled, or to reduce the size of a solid mix of raw materials (as in rock ore), so that pieces of different composition can be differentiated.

Cone Crushers - Mineral Processing & Metallurgy

The working principle of Cone Crushers is explained to understand what application to best use the fine cone crusher in.

Cone Crusher Reduction Ratio - loodgieter-reviews.nl

Cone crusher reduction ratio. Cone crusher reduction ratio hfc refrigerants 55 hst hydraulic cone crusherhst series hydraulic cone crusher is combined with technology such as machinery, hydraulic pressure, electricity, automation, intelligent control, etc , representing the most adv... Read More; Cone crusher reduction ratio manufacturer ...

Reduction Ratio Crushing No Of Crusher - …

Reduction Ratio Of Line Crusher maselwafamilyfunerals. reduction ratio crushing no of crusher mmc. reduction ratio crushing no of crushers Construction Planning Equipment CHAPTER The reduction ratio is the ratio of crusher feed size to product sizeGyratory crushers provide continuous crushing action and are used for both primary andreduction ratio crushing no of crushers,total reduction .