Jaw crusher - LinkedIn SlideShare

• Working Principle Of A Jaw Crusher • A jaw crusher uses compressive force for breaking of particle. • A Jaw Crusher reduces large size rocks or ore by placing the rock into compression. A fixed jaw, mounted in a "V" alignment is the stationary breaking surface, while the movable jaw exerts force on the rock by forcing it against the stationary plate.

The working principle of jaw crusher - LinkedIn …

The Working Principle of Jaw Crusher Jaw crusher consists of many parts, like eccentric draft , frame, large belt wheel,mobile jaw, flying wheel, toggle plate, toggle plate, gap adjustment screw and so on.The main function of jaw crusher to crush large rocks into smaller rocks, gravel,rock dust and gravel to satisfy different requirements for the products. Jaw crusher produced by Xiazhou is driven-squeezing …

jaw crusher working principle ppt - Popular …

The working principle of jaw crusher - SlideShare. Jul 24, 2012 ... Jaw, impactor, cone crusher Shanghais largest production base, China famous crusher equipment ... The Working Principle of Jaw Crusher Jaw crusher consists of many parts, like eccentric draft .... Roll crusher.ppt. Read More

The Working Principle Of A Jaw Crusher - Editors …

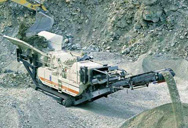

The working principle of the jaw crushers is very simple. Powered by a diesel or gas motor, the jaw crusher brakes materials in a crushing chamber. The materials are pushed inside the chamber from the top opening and when crushed they are released through the bottom opening. The crushing power of the jaw crushers depends on the size of the chamber. The bigger the chamber, the more powerful the jaw …

Mine Crushers Working Principle And GIF Pictures …

Common Crusher Working Principle and GIF: 1. Jaw Crusher. The jaw crusher periodically crushes the ore clipped to the fixed jaw plate by means of movable jaw plate. 2. Cone Crusher. The ore block is between the inner and outer cones. The outer cone is fixed and the inner cone sways eccentrically, crushing or breaking the ore block clamped in it. 3. Roller Crusher. The ore block is mainly ...

Jaw crusher: types, principle and applications

principle of jaw crusher This jaw crusher uses motor as its power. Through the motors wheels, the eccentric shaft is driven by the triangle belt and slot wheel to make the movable jaw plate move ...

The Working Principle of Jaw Crusher - YouTube

01.04.2008 · Therefore, the materials in the crushing cavity composed of fixed jaw plate, movable jaw plate and side-lee board can be crushed and discharged through the discharging opening. Loading...

Jaw crusher working principle - YouTube

14.04.2015 · Our company provides jaw crushers with different sizes. The fixed jaw plate, swing jaw plate and guard plate at both sides are made of wear-resistant high manganese steel with good wear resistance ...

Impact Crusher Working Principle

Starting from the base working principle that compression is the forcing of two surfaces towards one another to crush the material caught between them. Impact crushing can be of two variations: gravity and dynamic. An example of gravity impact would be dropping a rock onto a steel plate (similar to what goes on into an Autogenous Mill). Dynamic impact could be described as material dropping ...

Gyratory crusher working principle and diagram

Gyratory crusher working principle and diagram. gyratory crusher working principle and diagram Computer Aided Design of Jaw crusher email protected NIT Rourkela 13 Working Principle 14 Schematic Diagram of a jaw crusher analysis of single toggle jaw crusher shows that the forces on the moving jaw plate at different

Stone Crusher Working Principle With Drawing …

Jaw crusher working principle ppt new working principle of jaw crusher hammer mills operate on the principle that most materials will grind jacobson model 2442 hammermill cone crushera working principle of hammer mill coal grinder hammer crusher working principlecrusher the hammer mill sep 23 2014 hammer mills work in the principle that most materials will crush . Click to view; Stone Crusher ...

Gyratory Crusher l Introduce, Working Principle - …

Crusher Working Principle The primary gyratory crusher breaks the material by feeding mouth into the two rollers between the extrusion crushing, finished materials naturally fall. In case of too hard or can not be broken, the roller crusher by hydraulic cylinder or the role of …

Jaw Crusher Working Principle - Gravel Mill

Jaw Crusher Working Principle. Jaw crusher is widely used in industrial and mining enterprises , this is because the aircraft structure is relatively simple , and has a large range of models . Jaw crusher is mainly used as the primary crusher. It can be used with mineral processing equipment , gravel ancillary equipment, it also can be used alone. Get Price Inquiry. Structure of jaw crusher ...

What is the jaw crusher working principle, …

Working Principle of Jaw crusher When small jaw crusher works,The belt and belt pulley are driven by a motor, and the movable jaw moves up and down via eccentric shaft. The angle between fixed jaw and movable jaw becomes smaller when the moving jaw runs down, then the materials are crushed into pieces....

Jaw Crusher: Range, Working Principle, …

Jaw Crusher Working Principle. A jaw or toggle crusher consists of a set of vertical jaws, one jaw being fixed and the other being moved back and forth relative to it by a cam or pitman mechanism. The jaws are farther apart at the top than at the bottom, forming a tapered chute so that the material is crushed progressively smaller and smaller as it travels downward until it is small enough to ...