rotary kiln iron ore pellet process in Indonesia

kiln iron–ore pellet induration process PDF Free . A Dynamic Mathematical Model of the Complete Grate/Kiln Iron-Ore Pellet Induration Process J.A. THURLBY Induration (drying and hardening) of iron ore pellets is an energy-intensive feed preparation step for both the blast furnace and direct reduction routes to iron.

Iron Ore Dust Pellet Process - thgroup.co.za

Process. Direct reduction processes can be divided roughly into two categories: gas-based, and coal-based. In both cases, the objective of the process is to drive off the oxygen contained in various forms of iron ore (sized ore, concentrates, pellets, mill scale, furnace dust, etc.), in order to convert the ore to metallic iron, without melting it (below 1,200 °C (2,190 °F)).

iron ore dust pellet process stone crusher machine

iron ore pellet plant process. iron ore pellet plant process XSM excellent mining crushing machinery products or production line design, the company is committed to building the Chinese brand mine crushing and processing machinery, mainly crusher, mill, sand making our products (iron ore pellet plant process) in more than one hundred of the worldsales of countries and regions.

Rotary Kiln Iron Ore Pellet Process From Malaysia- …

Rotary Kiln Iron Ore Pellet Process. Rotary kiln iron ore pellet process res59beeposit formation in the gratekiln process hjalmar lundbohm aug 26 2013 cover picture information kiln in an iron ore pellet production plant the gratekiln process is a challenge for the iron ore pellet production industry can be used for the rotary kiln . Click to view

Iron Ore Dust Pellet Process - lancaster-watches.de

,iron ore pellet containing coal,,,, ,1123 taconite ore processing ,50 years of iron ore pelletizing experience and innovation,china iron ore pellets wholesale ,deposit formation in a grate,dust and iron ore processing ,effect of recycling blast furnace flue dust as pellets on ,how to process make iron ore pellets binq mining,iron ore fines and blue dust processing ,iron ore fines and blue ...

Direct reduced iron - Wikipedia

07-10-2005 · Process. Direct reduction processes can be divided roughly into two categories: gas-based, and coal-based. In both cases, the objective of the process is to drive off the oxygen contained in various forms of iron ore (sized ore, concentrates, pellets, mill scale, furnace dust, etc.), in order to convert the ore to metallic iron, without melting it (below 1,200 °C (2,190 °F)).

Iron ore - Wikipedia

Iron ores are rocks and minerals from which metallic iron can be economically extracted. The ores are usually rich in iron oxides and vary in color from dark grey, bright yellow, or deep purple to rusty red. The iron is usually found in the form of magnetite (Fe 3 O 4, 72.4% Fe), hematite (Fe 2 O 3, 69.9% Fe), goethite (FeO(OH), 62.9% Fe), limonite (FeO(OH)·n(H 2 O), 55% Fe) or siderite (FeCO ...

Introduction to Iron ore Pellets and Pelletizing …

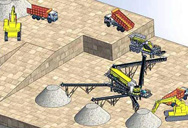

Process technology. There are four stages involved in the production of iron ore pellets. These stages consist of (i) raw material preparation, (ii) formation of green balls or pellets, (iii) induration of the pellets, and (iv) cooling, storage and transport of pellets.

Iron Ore Pelletizing Process: An Overview

The iron ore pelletizing process consists of three main steps: 1. Pelletizing feed preparation and mixing: the raw material (iron ore concentrate, additives anthracite, dolomite and binders are prepared in terms of particle size and stone specifications, dosed, and mixed together to feed the pelletizing process; 2.

iron ore dust pellet process - …

Iron ore pellet feed fines (PFF) The iron ore pelletizing process is marked by spherical pellets in a nar-row stone size distribution ranging between 9 mm and 15 mm The raw material in the process consists of iron ore ( 100 μm), binders (ie ben-tonite) and additives such as coal dust The moisture of the raw mate-rial can be variable.

Iron Ore Processing for the Blast Furnace

blast furnace process. The iron ore concentrate is now mixed and ready for the pelletizing process. Pelletizing A pellet plant contains a series of balling drums where the iron ore concentrate is formed into soft pellets, in much the same manner that one rolls a snowball, to make a pellet about the size of a marble (between 1/4" and 1/2").

Iron Oxide Pellet - an overview | ScienceDirect Topics

The stone process consists of reducing iron ore introduced in the form of iron oxide pellets at the top of the furnace by an appropriate amount of metallurgical coke. But the impurities contained in iron pellets and metallurgical coke also have to be melted to be eliminated.

IRON ORE PELLET PRODUCTION AT LKAB - SINTEF

Iron Making Process 100 people in R&D (LKAB 4200) 15 with PHD, 60 MSc / BSc, 15 Technician, 10 lab worker 30 % Women (LKAB 14 %) Annual operational cost R&D 250 MSEK R&D ORGANISATION Production Process Crude ore Concentrate Green Pellets Sintered Pellet

Iron Ore Processing Technology Pellet

Iron ore pellet is a kind of agglomerated fines which has better tumbling index when compared with the iron ore and it can be used as a substitute for the iron ore lumps both in the BF and for DRI production. Read More; Deposit Formation In A Grate-Kiln Plant For Iron-Ore. 2019-12-12Slag formation in the grate-kiln process is a major problem ...

Pellet Process Uses and Exposures May 2010 - The Iron Platform

Pellets are primarily used in blast furnaces and are also used in DR-plants. Occasionally pellets are used in the steel process. Pellets are stored in bunkers before charging to the blast furnace. The mixture of iron bearing materials (iron ore rubble, sinter and/or pellets) and additives (flux material) are known collectively as the "burden".

Pellet Furnace Iron Ore Sintering - HeNan Mining …

The Sintering Process Of Iron Ore Fines Ispatguru. Sintering is a thermal process carried out at 1300 deg C to 1400 deg C by which a mixture of iron ore return fines recycled products of the steel plant industry such as mill scale blast furnace dusts etc. slag forming elements fluxes and coke fines are agglomerated in a sinter plant with the purpose of manufacturing a sintered product

manufacturing process of sinter from iron ore dust

Iron Dust From Crushers - Crusher USA 2014310-About iron dust from crushers-related information:cgm crusher grinding mining manufacturing process of sinter from iron ore dust iron …

Influence of Pellet Size on Quality and Microstructure of ...

2. Pelletisation Process Pellets required for the present study were collected from a commercial straight-grate pellet plant of 3 Mt/year capac-ity. Production of iron oxide pellets from iron ore fines in-volves different operations like drying of ore fines to re-move the moisture and grinding to …