Crusher - Wikipedia

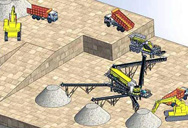

A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, sand or rock dust.. Crushers may be used to reduce the size, or change the form, of waste materials so they can be more easily disposed of or recycled, or to reduce the size of a solid mix of raw materials (as in rock ore), so that pieces of different composition can be differentiated.

Primary Crusher - an overview | ScienceDirect …

The primary coal crushers may be of different types such as: (1) coal jaw, (2) coal hammer, and (3) ring granulator. Secondary coal crusher: Used when the coal coming from the supplier is large enough to be handled by a single crusher. The primary crusher converts the feed size to one that is acceptable to the secondary crusher.

Primary Crushing - Mineral Processing & …

26-02-2016 · The term “primary crusher,” by definition, might embrace any type and size of crushing machine. The term implies that at least two stages of crushing are involved, but in many cases the machine which performs the function of initial crusher is the only crusher in the plant. The factors influencing the selection of a crusher for this service are much the same, regardless of how many ...

Mobile Primary Crusher Equipment In India

Mobile Primary Jaw Crusher is our star product and has Aggregate Equipment,Jaw Crusher,Feeding manufacturer of primary crusher for coal in india Chat Online 30 20 primary jaw crusher india – Crusher …

importance of primary crushing - ocmd.co.za

The primary crusher is most of the time a jaw crusher. what is the important of secondary crusher | Quarry Crusher . Used Cone crushers. Cone crushers are normally used as a secondary crusher but can be used as a primary crusher if used in processing a sand and gravel deposit.

Crusher - an overview | ScienceDirect Topics

13.3.1.2 Secondary Crusher. The secondary crusher is mainly used to reclaim the primary crusher product. The crushed material, which is around 15 cm in diameter obtained from the ore storage, is disposed as the final crusher product. The size is usually between 0.5 and 2 cm in diameter so that it is suitable for grinding.

How Do I Know Which Primary Crusher Is Best …

The primary reduction of coal from open pit or underground sources to a transportable and marketable product size, as well as further processing by cleaning plants, can be accomplished with a variety of crusher types. Heres how to choose the best one for your coal application.

P&Q University Lesson 7- Crushing & Secondary …

02-09-2019 · Today, primary crushing is viewed as more important within the balance of production and proper sizing needs. The size and type of the primary crusher should be coordinated with the type of stone, drilling and blasting patterns, and the size of the loading machine. Most operations will use a gyratory, jaw or impact crusher for primary crushing.

Crushers - All crusher types for your reduction …

One of the most important characteristics of a primary crusher is its capacity for accepting feed material without bridging. A large primary crusher is, naturally, more expensive than a smaller one. Therefore, the investment cost calculations for primary crushers are compared together against the total costs of primary stages, including quarry face clearing, blasting, and drilling costs.

Selecting the right crusher : Pit & Quarry

25-07-2018 · The most important characteristics of a primary crusher are the capacity and the ability to accept raw material without blockages. A large primary crusher is more expensive to purchase than a smaller machine. For this reason, investment cost calculations for primary crushers are weighed against the costs of blasting raw material to a smaller size.

components of a secondary crusher - Ketel …

The primary crusher is the engine that drives the rest of the plant; it’s the workhorse that takes blast feed sizes and reduces them to sizes that are manageable for other site components – the belts, the screens, and eventually any secondary crushers – on the road to a finished product.

Primary Crusher Selection & Design

How you select your primary crusher will be based on factors like moisture content, maximum rock lump size, material density SG, abrasion index, degradability and it being prone to dusting or not. The crusher capacities given by manufacturers are typically in tons of 2,000 lbs. and are based on crushing limestone weighing loose about 2,700 lbs. per yard3 and having a specific gravity of 2.6 ...

New to Mining? Here are the Most Common …

Regular training is essential and understanding the machines you’re working near or operating plays an important role in all aspects of the industry. ... (ROM) material is normally transported to the primary crusher by haul trucks, and in underground mining operations it is conveyed to the primary crusher.

TLC for Primary Crushers | E & MJ

Primary gyratory crushers are easily the hardest working piece of fixed plant on a mine site. ... “It’s also important to understand that you need to optimize a primary crusher in tandem with the downstream crushing and screening circuit to create system efficiency,” said Lindberg.

Mining Industry: What is the difference between …

Jaw crusher, impact crusher and cone crusher are most selling stone crushers in modern crushing plant. PE jaw crusher is important primary crushing equipment in crushing plant, which is famous for high reduction ratio and great crushing capacity. ...

primary crusher - Vertaling Engels-Frans

Online vertaalwoordenboek. FR:primary crusher. Mijnwoordenboek.nl is een onafhankelijk privé-initiatief, gestart in 2004.

primary crusher - eefschrijft.nl

Joyal-Jaw Crusher,Jaw Crusher For Sale,Jaw Crusher ... 19 rows The JOYAL Jaw Crusher is widely used in mining, building materials, stone industry, metallurgy and so on. The Jaw Crusher is suitable for primary and secondary crushing all kinds of minerals and …

most important crushing ratio antimony stone …

most important crushing ratio antimony stone crusher for sale For each project scheme design, we will use professional knowledge to help you, carefully listen to your demands, respect your opinions, and use our professional teams and exert our greatest efforts to create a more suitable project scheme for you and realize the project investment value and profit more quickly.

important parts of impact crusher - …

Important parts of impact crusher Honduras. Important parts of impact crusher Honduras. Apr 26 2017 · Product experts and Canadian distributors representing eight global manufacturers took part in an indepth look at the mobile impact crusher of today its evolution and future trends With typical capacities from 100 to 500 tons per hour mobile impact crushers are especially ideal for smaller ...