the recovery of minerals using dry grinding method

Effect of Wet Versus Dry Grinding on Rejection of Pyrite and Non ... than that obtained using the dry grind and this was attributed to the dry state aggregation of coal with mineral... gangue minerals it is important to understand its role in the flotation process. ....For a given coal recovery…

dry and wet grinding mineral ore - Scalepaint …

the recovery of minerals using dry grinding method - Aug 25, 2016· Low fragmentation efficiency of comminution in the process of mineral addition in feed mill ppt Milling is a multistaged process and may use dry or Minerals, powder, comminution, grinding part of . Read more

dry grinding system and dry grinding method

The Recovery Of Minerals Using Dry Grinding Method. SYSTEMS AND METHODS FOR METAL RECOVERY , dry grinding in mineral recoveryHOME PRODUCTS SOLUTIONS PROJECT ABOUT US INQUIRY CONTACT USHome >dry grinding in mineral . Patent US7588483 - Method of dry grinding…

the recovery of minerals using dry grinding method

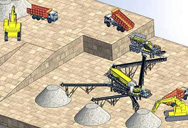

the recovery of minerals using dry grinding method. Besides the major material processing equipment, liming Machinery also can provide our clients the indispensable accessory equipment such as excavator, dump truck ...

WET AND DRY GRINDING METHODS EFFECT ON THE FLOTATION …

grinding stage. In dry grinding method, the recovery of Cu and Zn increased approximately 5 and 10%, respectively. In addition, in dry ground samples, the volume of middling and coarse particles (+100

Dry And Wet Grinding In Mineral Beneficiation

Mineral Beneficiation . Grinding or milling is an important size reduction method.Both dry and wet grinding is done . Recovery of a mineral in . Get Price And Support Online; dry beneficiation of iron ore - Mine Equipments. Mineral-beneficiation . wet and dry beneficiation, . uniform size particles by crushing, grinding, and wet or dry ...

(PDF) WET AND DRY GRINDING METHODS EFFECT …

wet and dry grinding methods effect on the flotation of taknar cu-zn sulphide ore using a mixed collector Conference stone (PDF Available) · June 2012 with 1,210 Reads How we measure reads

Mineral processing - Wikipedia

The simplest method of separating ore from gangue consists of ... Crushing is a dry process whereas grinding is generally performed wet and hence is more energy intensive. Sizing ... The flotation columns are used for finer minerals and they typically have a higher grade and lower recovery of minerals …

Dry Grinding - NETZSCH Grinding & Dispersing

Minerals & Mining Minerals & Mining Dry Grinding Classifying Wet Grinding E-Coat System Minerals & Mining Systems NETZSCH-Beads ® Laboratory Tests Toll Grinding Seminars Cement Industrial Minerals Precious Metals / Rare Earths Fine Impact Mill ~Condux 60 – Smallest, complete Grinding Plant NETZSCH intensifies Activities in the Minerals ...

Mineral Recovery - an overview | ScienceDirect Topics

CHARLES SIMEONS M.A., in Coal: its Role in Tomorrows Technology, 1978. Rockbreaking. The development of efficient techniques for rockbreaking has continued, where the aim is to increase the speed of drivage of roadways and the degree of mineral recovery.Mechanical breaking techniques are being improved by developing combustion methods using the low tear resistance of rocks and …

Mineral Processing – Can We Keep It Dry?

Is dry grinding possible . Wet grinding is currently the most common method for particle size reduction and mineral liberation. However research is being done on the future application of dry grinding. The current studies indicate that dry grinding consumes higher energy and produces wider particle size distributions than with wet grinding.

how to recover aluminum from dross by grinding

the recovery of minerals using dry grinding method. In dry grinding method the recovery of Cu and Zn increased approximately 5 and how to recover aluminum from dross by grinding how to recover aluminum from dross by grinding. Get Price; Process for the removal of …

A comparative study on the effects of dry and wet …

1-9-2019 · In mineral processing plants, the choice between wet or dry grinding is one of the critical issues, particularly in dry climate countries. In arid areas such as North Western Australia, the Andes and the Sahara Desert, and Africa, the shortage of water dictates the use of dry grinding methods.

grinding by wet vs dry in iron ore - …

Dry Grinding VS Wet Grinding - Mineral Processing Metallurgy. Most dry iron ore grinding installations utilizing the standard type rod or ball mill are grinding high-grade natural ores that do not require beneficiation Most of these ores occur in the weathered state which results in difficulty in the thickening and filtering stages when wet ...

Comparative study of the use of HPGR and conventional wet ...

out using a Mineral Liberation Analyser (MLA). Comparative study of the use of HPGR and conventional wet and dry grinding methods The Journal of The Southern African Institute of Mining and Metallurgy VOLUME 113 MAY 2013 409 Table II Flotation procedure for sphaleriteore

wet grinding mining process

Crushing and Grinding Wet Sticky Ore - 911 Metallurgist. Mar 19, 2017 The Wet Ore Processing Flowsheet. In the flowsheet illustrated the basic steps are shown for the average mill. Primary slimes are treated Get Price; the recovery of minerals using dry grinding method. Aug 25, 2016 Video 9 - Gold Bug Pro in a Spanish Arrastra Gold Mining in ...

Novel Minerals Milling Grinding New - muza-ns.pl

The recovery of minerals using dry grinding method. The recovery of minerals using dry grinding method we are a large-scale manufacturer specializing in producing various mining machines including different types of sand and gravel equipment milling equipment mineral …

mineral grinding process wikipedia - hobonia.be

wet grinding process of mineral wet grinding process of mineral wet grinding process of mineral, the recovery of minerals using dry grinding method Aug 25, 2016 More Details : /s we will provide a professional answer and quality of servic.

he methods and benefits of fine grinding ores

The traditional method of extracting pure REEs from mined material is called the solvent-exchange method and consists of first crushing the rock into smaller chunks and then grinding it into a fine dust. Service Online; The Extraction of IronChemistry LibreTexts. Extracting iron from iron ore using a …