Cement Process By Ball Mill - sport-hippique.nl

Cement manufacturing. The ball mill has a vital role in the cement manufacturing process. The mixed raw materials (cement raw meal) before cement production and the finished products (cement clinker) after cement manufacture need to be ground by cement ball mill. The grinding media balls in the ball mill are used in cement plant to help grind

Cement Ball Mill Process - sport-hippique.nl

Cement Ball Mill For Dry Process. 20191017cement ball mill in the process of production and processing has high grinding efficiency large output and compared with the general ball mill this ball mill can save more energy consumptionur company can design and manufacture a special cement ball mill to meet the actual needs of users according to the output and fineness requirements of users.

Cement Ball Mill Process - restaurant-le-billot.fr

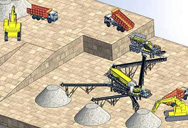

Cement Ball Mill Process Albumt. We can provide our customers the all-sided produce project such as aggregate production line, mineral ore processing plant, sand making plant and other construction recycle plant to satisfy their production request. Get Price And Support.

grinding media cement ball mill process calculation

Cement manufacturing - brief description of a cement mill. Cement clinker is usually ground using a ball mill. This is essentially a large rotating drum containing grinding media - normally steel balls. As the drum rotates, the motion of the balls crushes the clinker. The drum …

cement production process using a ball mill

Ball mill for cement making plant, ball mill works principle, China . May 22, 2014 Ball mill for cement making plant, ball mill works principle, China Ball mill through the discharging board thus the grinding process is finished. optimizing the control system of cement milling: process Scielo.br. mostly performed in closed circuits: The ball ...

Ball Mill & Roller Press for Cement Grinding Process

Nowadays, the cement grinding system has developed from the previous single ball mill system to ball mill + roller press system and vertical roller mill system. Today we will introduce three mainstream ball mill + roller press cement grinding processes that are often adopted in cement plants and cement grinding stations. 1.

The cement mill

Cement manufacturing - brief description of a cement mill. Cement clinker is usually ground using a ball mill. This is essentially a large rotating drum containing grinding media - normally steel balls. As the drum rotates, the motion of the balls crushes the clinker. The drum …

PROCESS DIAGNOSTIC STUDIES FOR CEMENT MILL …

A 1.5 mio t/a cement plant is having a closed circuit ball mill for cement grinding: The mill has been operating with satisfactory performance in-terms of system availability and output, however power consumption was on higher side. 3.1 System Description Mill Rated capacity 150 t/h OPC at …

Working principle of Ball Mill /ball cement milling ...

3-3-2015 · Ball mill is an efficient tool for grinding many materials into fine powder. The Ball Mill is used to grind many kinds of mine and other materials, or to select the mine. It is widely used in ...

Cement ball mill - CHAENG

CHAENG cement ball mill equipment can reduce energy consumption by 30% and increase the processing amount by 15-20% after transformation. The cement ball mill can perform dry process production and also wet process production, moreover it can do grinding and drying at the same time.

ppt for ball mill - nijhuisarchitectuur.nl

Cement Ball Mill |authorSTREAM. slide 1: Process introduction Compared to other traditional ball mill the cement ball mill of CHAENG can improve output by 1520 and the specific surface area of produced cement is 33003800 cm²/g and the fineness of product is easy to adjust so as to achieve high.

cement process plant with ball mill in india

cement grinding ballmill process at india. ball mill cement grinding process in india Grinding Mill ball mill cement grinding process in india 4.9 4546 Ratings ] The Gulin product line, consisting of Mill (grinding) Wikipedia A mill is a device that breaks solid materials into smaller pieces by grinding, crushing, or cutting.

Cement mixer turned into ball-mill to process gold …

10-7-2014 · Cement mixer turned into ball-mill to process gold ore NelsonStudios. Loading ... Ball Mill Critical Speed & Working Principle - Duration: 5:40. 911 Metallurgy Corp. 248,935 views.

Grinding Mill Cement Industry Last Process

Cement ball millcement production processCement epc . 2019-12-25 Cement ball mill in the process of production and processing has high grinding efficiency large output and compared with the general ball mill this ball mill can save more energy consumption.

cement ball mill in europe - yourenature.nl

Cement Ball Mill. 2020-7-4 Cement ball mill is not only suitable for over-flow grinding, but also applicable for cyclic close-flow grinding together with powder collector. There are two ways of grinding: the dry way and the wet way. Features 1. Can work with …