mining protocol for conveyors

Mining Protocol For Conveyors - Vriendenkring RZ Tienen. Page 1 of 4 | Conveyor Hazards Safety Factsheet: Hazards of Conveyors Conveyors are used to transport materials horizontally, vertically, at an angle, or around curves. Hazards depend on the type of conveyer, the material conveyed, the location of the conveyor, and how close the conveyer is to workers.

mining protocol for conveyors - carinransijn.nl

mining protocol for conveyors. 150-200TPH Cobble Crushing Plant. 300TPH Cobble Crushing Line In Russia. You can reach us by: If you are interested in our company or products, welcome to visit our company or local offices; you can also get contact with us through online consulting, demand table submission, e-mails and telephones.

Conveying - liming

In mining and minerals processing applications, conveying is often the most efficient way to transport material. liming offers a comprehensive range of conveyors, conveyor parts as well as repair, maintenance and optimization services for even the most challenging mining and …

Advanced Braking Technologies for Mining Conveyors

Mining Conveyors As seen in Engineering & Mining Journal October, 2015. In order to improve efficiencies and handle larger loads, mining conveyors and their belts have grown in size. As the larger capacity of inclined and declined conveyors with higher torques became more common, it became critical to engage the conveyor brakes in a gentler, controlled manner. Also, mine operators wanted …

Mining with a Heavy Industrial Conveyor Belt via …

Our engineering experts have many years of direct experience sourcing and designing conveyor belting for key mining applications and our national distribution network lets us deliver the belt you need right when you need it. Surface mining or deep mining. Large stone. Heavy ore. Quarries, magnetic separators, bucket elevators, coal transport, asphalt milling, street sweeping … you name it ...

Belt Conveyors employed in mining applications | …

Belt conveyor systems requiring anything up to 20,000 t/h capacity are anything but a rarity in mining. TAKRAFs know-how and significant experience in this area is a critical success factors to projects of such scaled and magnitude.

Four benefits of LoRa in mining – and how Rio …

13.08.2019 · The mining industry relies on conveyor belts to transport materials taken from the the mine for processing. Conveyer belts can run up to 10 miles across a mine, and to different locations throughout it. It is critical they work well; preventing incidents of damage and fires can help mines to reduce operating costs and increase profits. Transco Industries, which makes conveyor belt components ...

mccp mining conveyor control program

Integrated conveyor control ABB has developed the Mining Conveyor Control Program (MCCP) which is a software package loaded on to the drives control board of ABB’s ACS 800 variable speed drives. Use of IT and automation in mining and raw material handling the main drives control and with PROFIBUS DP to read diagnostic information.

Mining Conveyors & Processing Equipment | …

The mining, crushing, washing and drying of many metals and minerals is accomplished by the use of conveyors. Copper, Iron ore, taconite and uranium are metals that are conveyed using KWS Screw Conveyors and Belt Conveyors. Coal, limestone, sand, kaolin clay, potash and soda ash are minerals that we have conveyed from the mines to the crushers and other areas of the process. Our conveyors …

PAPER - Lightning Safety in the Mining Industry

How to defend against the lightning hazard at mining operations? We recommend adoption of a lightning hazard mitigation and safety planning process. This must be endorsed by senior mine management and Corporate-level engineering and safety management. 4 2. LIGHTNING BEHAVIOR & CHARACTERISTICS. 2.1. Physics of Lightning. Lightning’s characteristics include current levels up to …

Choosing Mining Belt Conveyor Manufacturers

NEPEAN Conveyors is a world class mining conveyor manufacturer responsible for some of the industry’s most advanced mining systems. Our products have been used for over 35 years by customers in overland and underground mining, ports, and other large bulk material handlings plants. Problems Our Mining Conveyor Systems Help Solve . When you choose NEPEAN Conveyors as your supplier of conveyor ...

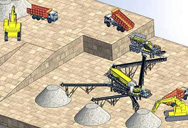

Conveyors - Quarry Mining

QUARRY MINING LLC did develop various type of single conveyor in light execution for low capacity but also in medium execution for our standard plants and in heavy execution for special application. Our conveyors have width of 500, 650, 800, 1000, 1200, 1400 and 1600mm while there is maximum flexibility for length.

Belt conveyors I thyssenkrupp

Mining Systems; Belt Conveyors . Belt conveyors . Overland conveyors provide the most effective way of transporting bulk materials over long distances. thyssenkrupp belt conveyor systems are custom-designed to meet the specific demands of the client’s needs, for the type and volume of material to be handled, the existing topography of the route, and prevailing climatic conditions. Our ...

belt conveyors - Mining Magazine

Vale activates emergency protocol for another dam. Geomechanics / Ground ... 30 JUL 2020. Irans HEPCO targets mining expansion. Fleet 29 JUL 2020. Underground Mining. Development; Fleet ; Technology / Innovation; Operational excellence; Geomechanics /Ground control; Latest from the Underground Mining Channel. Minova, Runaya in ground support JV. Geomechanics / Ground ... 31 …

Belt Conveyors employed in mining applications | …

Mobile Conveyor Bridges (MCBs) operate as flexible links between mining machines and bench conveyors and increase the operating range of the system. Mobile Transfer Conveyors. Mobile Transfer Conveyors (MTCs) are "multi use" equipment that are used to both increase performance and flexibility of many mining operations. Mobile transfer conveyors work as a flexible connection between a mining ...

ACI World urges governments to follow …

Vor 23 Stunden · With the new protocol in place, international air transport can be restarted in a safe and efficient manner, and people and goods can travel freely without increasing the risk of infection. According to ACI, risk-based and proportionate measures are required to implement mitigation measures that are currently in place while considering the need for economic recovery. To this end, governments ...