Gold Sulfite

Sulphites of Gold, alkaline sulphites, or sulphur dioxide, which reduce gold trichloride easily, do not produce the same effect on a solution of an alkaline aurate. If sodium bisulphite is added to a boiling solution of sodium aurate (NaAuO2) a yellowish precipitate is formed, soluble in excess of sodium bisulphite, and consisting of a double sulphite of gold and sodium, or sodium auro ...

Sulphide Gold | Gekko

When gold is associated with sulphides, it can be either fully encapsulated by the sulphide particle or partially liberated, i.e. exposed on the edge of the sulphide mineral. Sulphide complex gold can occur in a wide range of particle sizes. Because cyanide cannot always leach sulphide-associated gold, regrinding the ore is typically required to expose the free gold for recovery by intensive leaching.

Pumps and Systems for Mining | LEWA

48 rows · Elution stripping of gold adsorbed onto activated carbon: Ferrous Sulphate: Cyanide …

sulphate in gold mining - geefmijdekans.nl

Sulphate in gold mining Copper sulphate is a copper salt and mainly used in agriculture principally as a prior to wire drawing and in various copper plating processes The mining industry Molluscicide for the destruction of slugs and snails particularly the snail host of the liver fluke oxidechloridecyanide and cuprammonium pounds.

Uses of copper sulphate for agriculture, industry and medicine

The metal industry uses large quantities of copper sulphate as an electrolyte in copper refining, for copper coating steel wire prior to wire drawing and in various copper plating processes. The mining industry employs it as an activator in the concentration by …

sulphate in gold mining - ME Mining Machinery

Gold cyanidation (also known as the cyanide process or the MacArthur-Forrest process) is a hydrometallurgical technique for extracting gold from low-grade ore by converting the gold to a water-soluble coordination complex. It is the most commonly used leaching process for gold extraction. Sulphate In Gold Mining vriendenkringrztienen.be

Mining Reagents - Orica

Caustic Soda (Liquor & Pearl) Elution stripping of gold adsorbed onto activated carbon Ferrous Sulphate Cyanide detoxification in gold mining process Hydrochloric Acid Pre‑elution treatment of activated carbon in gold mining Lead Nitrate Accelerator in gold cyanidation Sodium Bisulphite (SBS) Cyanide detoxification in gold mining

Gold Precipitation Methods

Metallurgical ContentClarification of Gold SolutionGOLD PRECIPITATIONGOLD PRECIPITATION BY ZINCChemistry of Gold PrecipitationPreparation of Gold Pregnant Solutions ...

Gold cyanidation - Wikipedia

The oxidation of sulfur compounds to sulfate ions avoids the consumption of cyanide to thiocyanate (SCN −) byproduct. Recovery of gold from cyanide solutions. In order of decreasing economic efficiency, the common processes for recovery of the solubilized gold from solution are (certain processes may be precluded from use by technical factors):

Nickel Investment Opportunities: 5 Junior Mining Companies ...

Jul 14, 2020 · Recently I featured 20 gold mining companies to keep an eye on as the market turns in favor of gold. Well, today my focus is on Nickel. Many industry leaders and professionals are predicting supply and demand issues in the coming years and I believe we are on the verge of …

What is Sulfide Mining? | Mining Action Group

Metallic sulfide mining (aka hard rock mining) is the practice of extracting metals such as nickel, gold and copper from a sulfide-rich ore body.

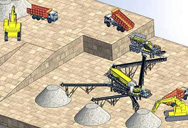

Heap leaching - Wikipedia

Heap leaching is an industrial mining process used to extract precious metals, copper, uranium, and other compounds from ore using a series of stone reactions that absorb specific minerals and re-separate them after their division from other earth materials. Similar to in situ mining, heap leach mining differs in that it places ore on a liner, then adds the chemicals via drip systems to the ...

4 Gold-Mining Stocks to Watch | Stock Market News | US News

Jul 01, 2020 · SSR Mining ().For a smaller company, Graf likes SSR Mining. The company is in the midst of completing a merger with Alacer Gold Corp. (ASR), …

Differences Between Sulfides And Oxides | Difference Between

Besides gold, diamonds, silver, copper, and bronze, which most people know are popular and expensive minerals found in mining, you should also be aware of different elements also in demand in the mining industry. The sulfides and the oxides are two examples, which are consistently mistaken for each other. Here is where they differ:

The 10 Biggest Mining Stocks | The Motley Fool

Oct 12, 2019 · The combined company operates a portfolio of 14 gold mines in North and South America, Africa, and Australia as well as stakes in two gold mining joint ventures (JVs). In addition to gold…

ammonium sulfate production from gold mining

ammonium sulfate production from gold mining Rock Explosives is a global leader in the development and production of ammonium sulfate Read more Get More Info Gold cyanidation Wikipedia The expansion of gold mining in the The oxidation of sulfur compounds to sulfate ions Despite being used in 90% of gold production: gold cyanidation isget price

ammonium sulfate production from gold mining

ammonium sulfate uses mining list of advantages to mining gold are the advantages and effects of floodplain and terrace pit mining gold mines production in Inquire Now mining of sulfates process and place crusherasia

Zinc Mining, Zinc Mine, Zinc Mines, Zinc Places, Zinc ...

Zinc is a bluish-white metallic stone element that is ductile in its pure form but in the commercial form it is brittle at room temperature and becomes ductile on slight heating. It occurs amply in minerals and is considered an essential micro nutrient for both plants and animals.

Market enjoys a strong week as technology, health stocks ...

Aug 15, 2020 · Recent drilling at Trigg Mining’s Lake Throssell sulphate of potash project in WA has returned a high-grade SOP product. Assays returned up to 14,500mg/L – equivalent to 14.5kg per square metre. All-up, 77 brine samples were collected and assayed on average 11,300mg/L, with 90% of the holes drilled to date returning grades exceeding 10,000mg/L.