Cement Plants located in United States

Cement plant locations and information on United States can be found below. For full access to the database, purchase The Global Cement Report™, 13th Edition.

The Cement Plant Operations Handbook 6th Edition

Fully revised and updated with improved content, the new Sixth Edition of the Cement Plant Operations Handbook is now available. Covering some 300 pages, the cement industry’s favourite technical reference book offers in-depth information on the various aspects of cement production.

Operation Guide for Vertical Roller Mill in Cement Plant ...

Vertical Roller Mill Operation in Cement Plant The vertical roller mill (VRM) is a type of grinding machine for raw material processing and cement grinding in the cement manufacturing process . In recent years, the VRM cement mill has been equipped in more and more cement plants around the world because of its features like high energy ...

Cement kiln - Wikipedia

Oct 01, 2006 · Thus, it is necessary for operators of cement kilns to closely monitor many process variables to ensure emissions are continuously minimized. In the U.S., cement kilns are regulated as a major source of air pollution by the EPA and must meet stringent air …

Kiln Operation In Cement Plant-rotary Kiln

Cement Kiln Maintenance The Cement Institute, Kiln maintenance learning outcomes introduction the kiln is defined as a thin rotating cylinder from a mechanical and structural point of view with respect to a cement plant are kilns and mills in the case of kilns heat is applied to the cylinder as it ro Kiln Operation In Cement Plant

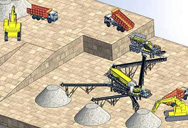

Stacker and reclaimer systems for cement plants

in the cement industry, in cases where the raw material stone composition varies greatly. Prehomogenisation is used primarily for the main components in cement production, i.e. limestone and clay. With the increasing variation in the grades of coal used for coal firing installations, there is a growing need for prehomogenisation and storage of

(PDF) Cement plant operation handbook | jorge pinedo ...

Academia.edu is a platform for academics to share research papers.

How does a concrete batch plant work | Operation of ...

May 25, 2017 · Before we understand the working or operation of a concrete batch plant.It is important to understand the basic components and structure of a batching plant. We have mobile concrete plants installations in Philippines’s city like: Bulacan, Cavite and Pampanga. It is a machine that combines various ingredients like aggregates, sand, water, cement and additives.These components are first …

Optimising Cooler Operation | World Cement

Jul 10, 2020 · Valentina Bordei, thyssenkrupp, discusses the optimisation of clinker coolers to meet industry demands for energy efficiency and low maintenance. In every cement plant, the cooler operation has a crucial impact on operating performance, clinker quality and overall productivity.

Abay Cement plant to start operation in 2021 - Cement ...

Jun 03, 2020 · Ethiopia: Samuel Halala, the director of Ethiopian stone and Construction Inputs Industry Development, says that the Abay Cement plant is 60% complete and due to start operation in 2021. The 2.5Mt project is located near Degen in Amhara Region, according to New Business Ethiopia. It has an investment of around US$260m.

Cement manufacturing - components of a cement plant

Cement manufacturing: components of a cement plant. This page and the linked pages below summarize the cement manufacturing process from the perspective of the individual components of a cement plant - the kiln, the cement mill etc.. For information on materials, including reactions in the kiln, see the Clinker pages.

Obajana Cement Plant - ::Welcome to Dangote Cement Plc.::

Capacity : 2 x 2.5 MTPA + 1 x 6 MTPA of Cement. Raw Material Sources. Limestone : Obajana Mines Correctives/ Additives : Obajana Mines Gypsum : Other Sources Power Source : 3 x 45 MW Captive Power Plant Fuel Source : Gas, Coal, LPFO Cement Packing : 8 ( L1 & 2) + 10 ( …

U.S. Portland Cement Industry: Plant Information Summary

December 31, 2013 Page 1 U.S. Executive Summary The U.S. cement industry is comprised of 106 cement plants (99 clinker-producing plants and 7 grinding facilities) operating just under 100 mmt of clinker capacity and roughly 126 mmt of finish

PERFORMING A CEMENT PLANT OPERATIONS AUDIT - The …

Modern dry-process cement plants with an efficient grinding and pyro processing system, typically consume less than 700 kcal/kg-cl of thermal energy and 100 kWh/mt of electrical energy. Older plants with inefficient systems, combined with operational and maintenance failure, tend to have much higher energy consumption.

Cement Industry Overview

U.S. cement production is widely dispersed with the operation of 107 cement plants in 36 states. The top five companies collectively operate 49.6 percent of U.S. clinker capacity with the largest company representing 14.2 percent of all domestic clinker capacity.

We have to improve our operations to be more sustainable ...

Jul 31, 2020 · The Untervaz Cement Plant, in Switzerland. ... The CEO of LafargeHolcim told CNBC Thursday that the building materials firm had to improve operations so that sustainability became part of …

Cement Plant Operator Jobs, Employment | Indeed.com

337 Cement Plant Operator stone available on Indeed.com. Apply to Plant Operator, Operator, Mixer and more!